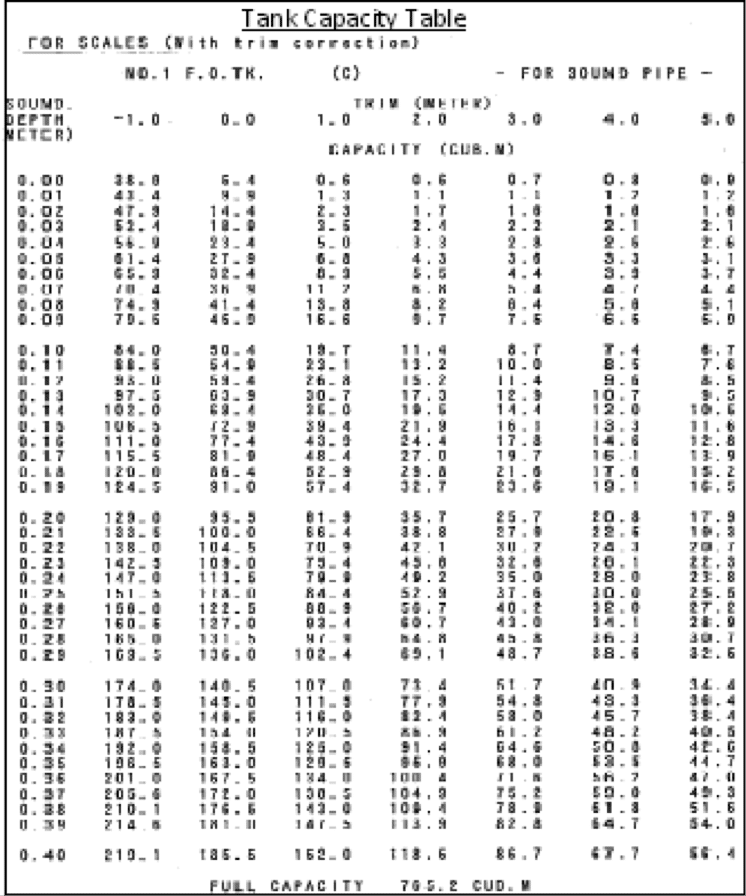

He knows less about Rocketry than I do, and I'm only in Rocketry 2. The new one has a masters in physics, but little experience. Our current teacher just replaced our old one, who retired. No one on campus, including our teacher, has been able to offer us much help. We're in a time crunch, and our project is so huge that we don't want to risk wildly guessing. We understand the importance of figuring things out on our own, but my partner and I have been researching for weeks without any luck. This nitrous tank is only part of our hybrid motor. It has a 10-inch diameter and is aimed to reach a 100,000 ft. It's currently my best bet, but I want to be sure as I can.Ĭould somebody please direct me to a source that could help me? Or, could someone please give me a rough idea of how to calculate a safe percent of ullage?ĮDIT: Just for reference, this Rocket is not small. Unfortunately, this source gave no context for the conditions of this tank. The best hint I've been able to find is that ullage may take up 20% of the tank. I can't tell if there's a generally accepted standard, or it's something that changes for every situation. We've found source after source giving either general definitions of ullage or safety-wise why it's so important, but we can't find anything that will actually explain anything about the process of calculating the percent ullage that we'd need. We've been searching both through textbooks and online sources about how to calculate ullage for the tank. We know the exact pressure, temperature and volume of the nitrous oxide itself, as well as what materials the tank will be made from. Electronic sounding gauge-Senses the pressure inside the sounding pipe or the tank and sends the signal to a receiver.Right now my friend and I are attempting to calculate the ullage for a tank of liquid nitrous oxide as part of our hybrid motor.Differential pressure guage-Uses the difference between two pressure points within a process system to give the level.

0 kommentar(er)

0 kommentar(er)